Case Study 6: Fleurieu Peninsula, SA, Dairy Farm

Tallemenco was contracted to conduct a detailed pumping energy efficiency audit in Sept 2020 on a modern 100 head dairy farm in the Fleurieu Peninsula, South Australia.

An 8 yr old 620’ long Center Pivot (CP) irrigated mixed pasture on the dairy farm. A 20 HP vertical multistage pump on a VFD lifted 253 gpm, with a TDH of 174 ft to the CP approx 1,700’ away via a 6” PVC pipe.

The audit measured pump efficiency plus friction losses across each major pipe and irrigation equipment sector. The pumped system had 80 AF/yr usage, approx $9,100/yr electricity cost at ave 37c/kWh and pumped head was 174’.

The CP operated over a considerable land undulation, ranging from 92ft lift at its highest, to 6’ lift at its lowest.

However, the nature of the undulation meant that the average lift was 46’ less that the highest lift.

The residual pressure at the end of the CP was 10 psi at its highest point.

Findings

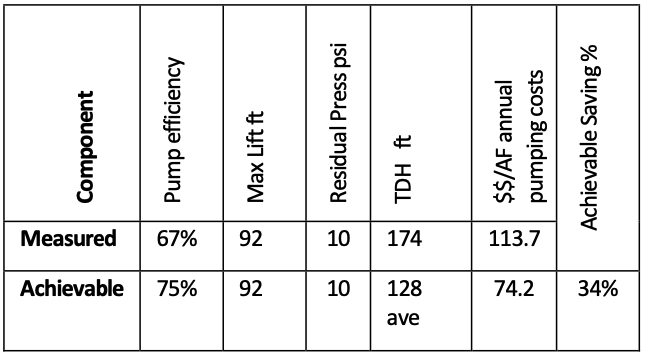

This table summarises the findings in terms of $$/AF attributed to deficiencies in the irrigation system.

The pump was found to be 8% down on efficiency, amounting to about $700pa additional electricity cost.

The pump was a higher head than required and was fitted with a VFD which was set for the optimum Hz to give optimal residual pressure at the CP’s highest elevation.

However, the system was not configured to take advantage of the elevation drop as the CP moved to its lowest elevation.

All it required was a Radio Pressure Transmitter at the end of the CP, telemetered back to the VFD input.

This modification would cost around $2,000 installed, including aerials.

The savings from this alone will amount to $2,400 pa, or an additional 26% saving.

This represents a ROI of less than 1.0 yr.

In this case, a pump test only would have missed the extra $2,400 pa (26%) attributed to the optimization of the hydraulics.

Quantifying pumping energy efficiency in an irrigation system has long been understood to be made with a simple pump test. Ignored was the significant additional potential energy savings available in irrigation system pipelines due to poor hydraulics.

The WATER PUMPING INSTITUTE’s aim is to educate water engineers in the art and science of identifying hydraulic in-efficiencies in irrigation (and other water) systems. This is achieved through its training course “Pumping System Master Class (US)” with “Fit for Purpose” software which comes with the training course.

These case studies have been compiled as living proof of the feasibility and practicality of identifying (or incorporating into new systems) up to 50% hydraulic savings from pumping system energy audits. These case studies demonstrate the importance and savings advantages of quantifying hydraulic efficiencies when conducting pumping energy audits.